-40%

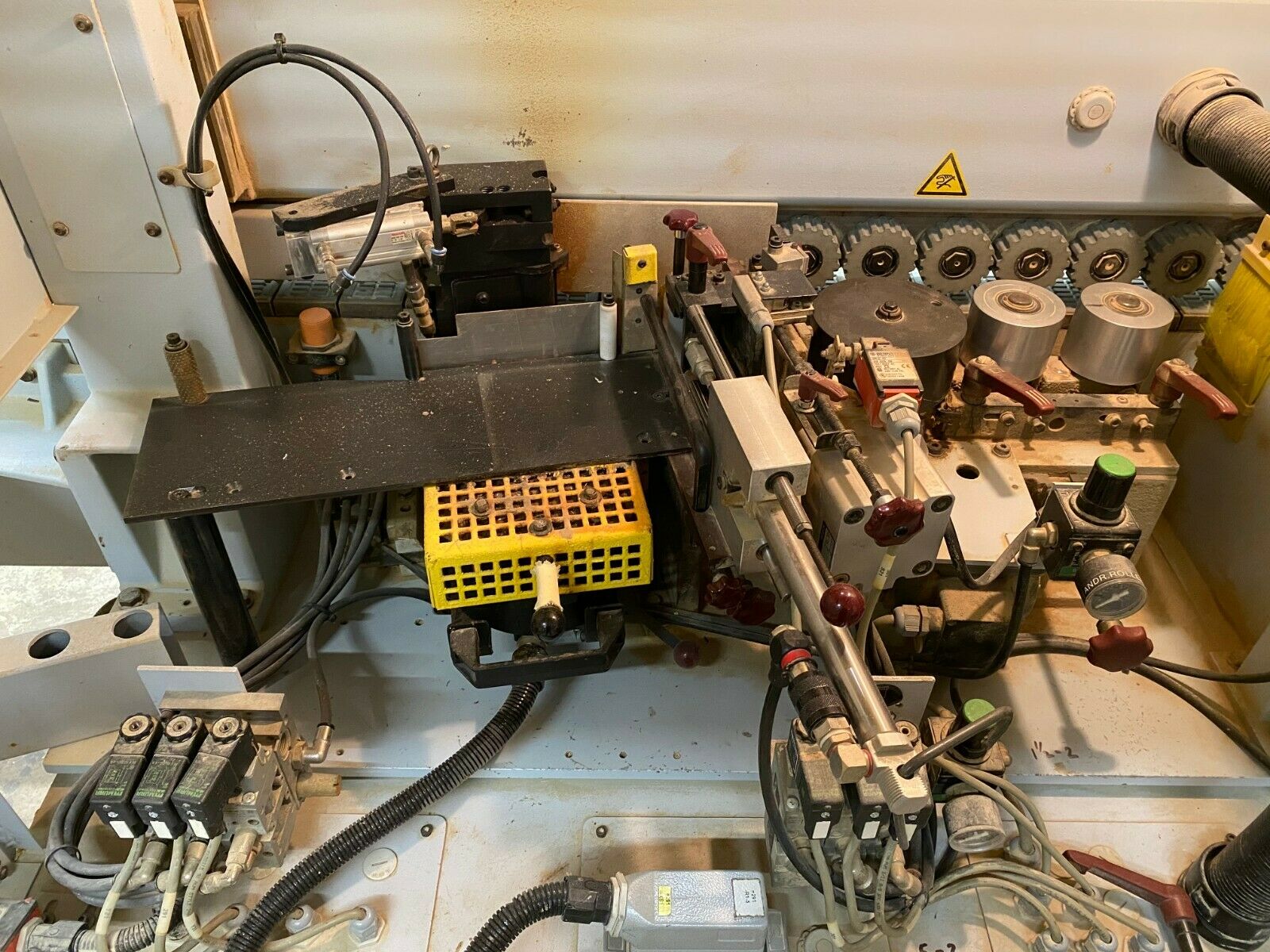

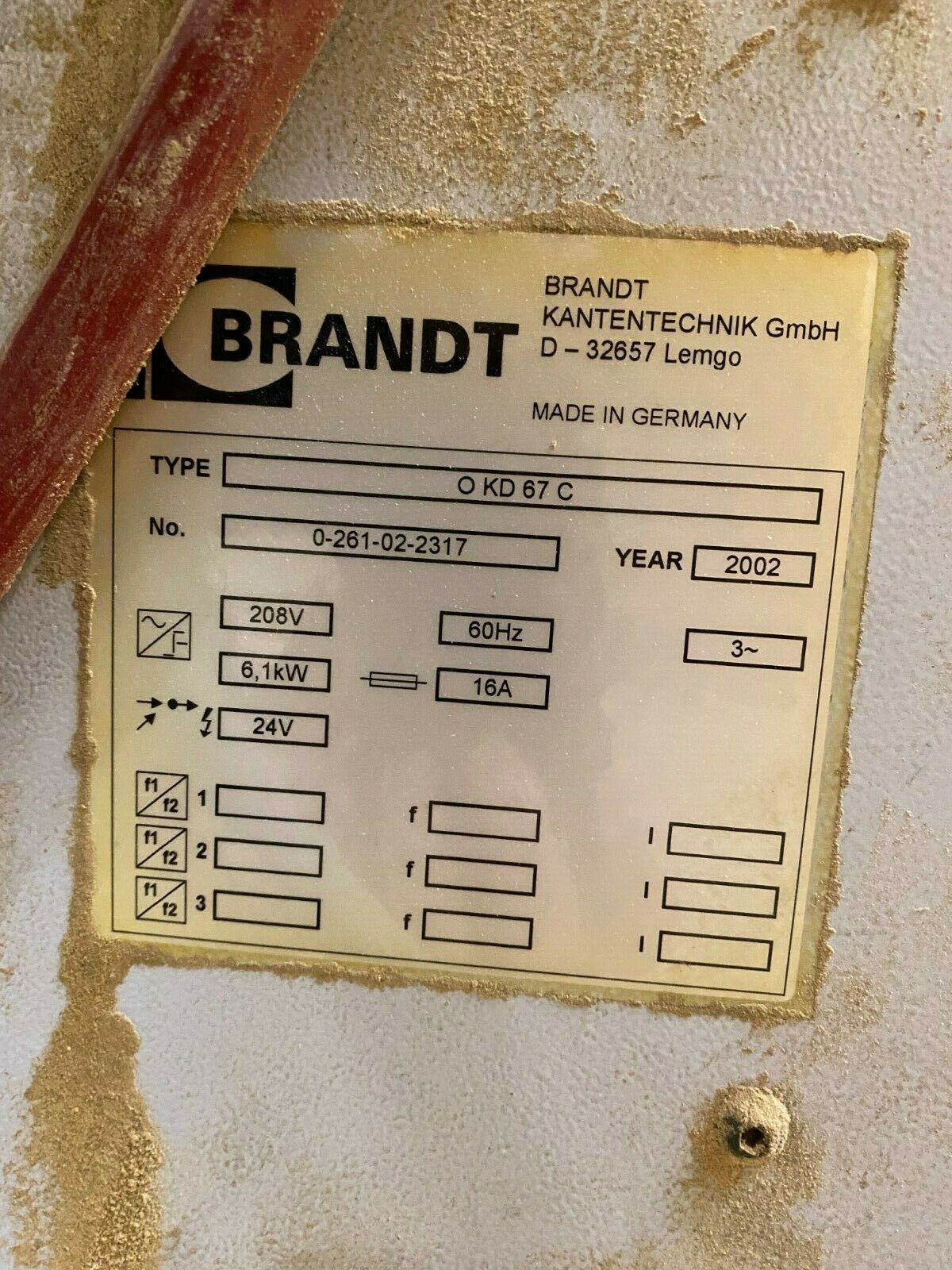

Brandt Automatic EdgebanderOptimat Model KD-67 C

$ 4077.21

- Description

- Size Guide

Description

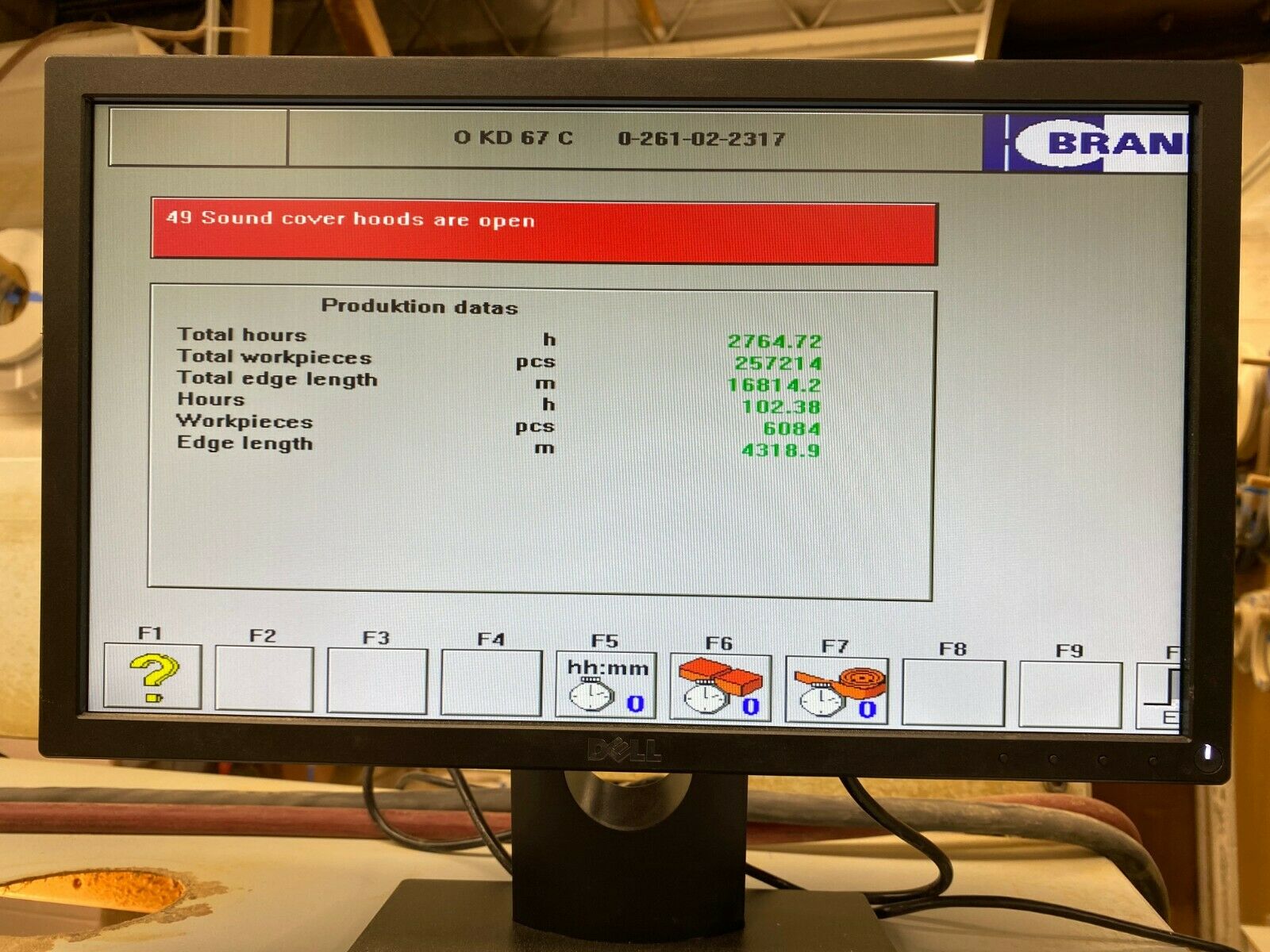

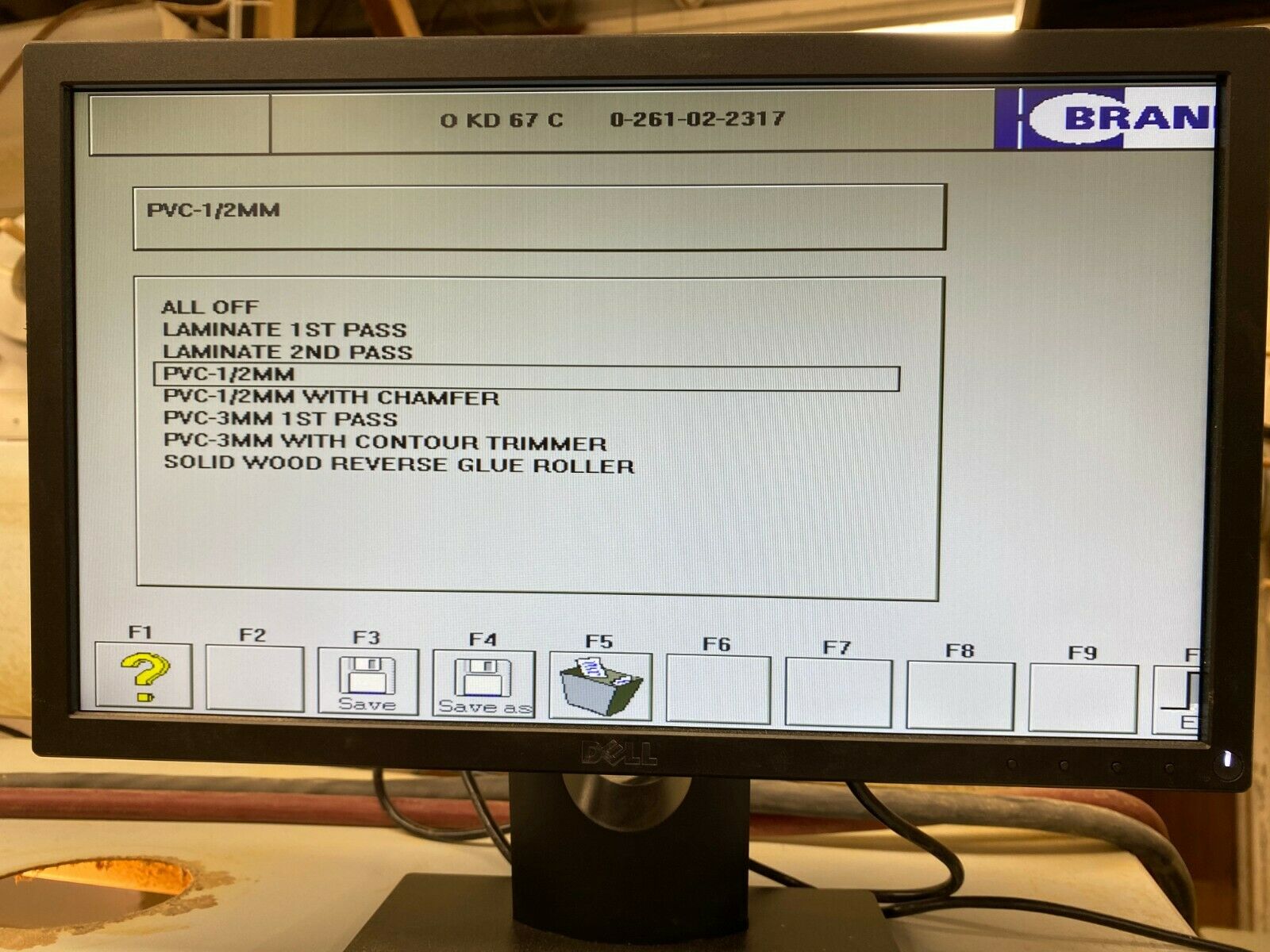

Optimat Model KD-67CPC-16 Program Control

-

Color matrix LCD screen display

-

8mb RAM

-

Internal Modem

-

Manual push button controls or program controloperation

Equipped with digital heightindicator.

Integrated electronic line controlsystem for increased reliability and diagnostic assistance.

No limit switches used for setting operatingunits.

Control panel located at machineinfeed for operator convenience.

Universal automatic magazine forstrip and coil feeding.

Large coil table (800 mmdiameter) to accommodate large coils of 3 mm PVC.

Hot melt granulate glueapplication system with

twelve minuteheat-up time.

Quick-change glue tank for easymaintenance and glue color change, if necessary.

Reversible rotation of glueapplication roller.

Retractable glueroller.

Strengthened precutter forcutting PVC (max. 3 x 45 mm) from the coil.

Infrared radiant quartz heatingunit between glue roller and pressure zone for optimum gluing strength.

First pressure roller driven andtwo idle pressure rollers.

Double motor end trimming unit

with straight and chamfercapability.

Chamfer up to 15

°

.

Programcontrolled indexing from straight to bevel end trimming.

Fine trimming unit

with digital “Quickset” system.

Tilt range 0 - 15

°

.

Program

controlled indexing.

Contour trimming unit

for profile corner trimming.

Sound enclosure with centralizeddust extraction outlet.

Scraping unit

for rigid PVC edges.

Program controlled indexing.

Buffing unit.

Electronic frequency changer forall trimming motors which also incorporates electronic motor brakes.

Electricalcomponents according to UL/CSA Listings.

Technical Specifications

Edgeband thickness

0.4 – 8 mm (0.016" -

5/16” )

Coil cutoff maximum

0.8 x 45 mm

3.0 x 45 mm (PVC)

Edgeband height

12 - 45 mm (1/2" – 1 ¾ ")

Panel length min.

160 mm (6 3/8")

Panel width min.

65 mm (2 3/8")

Panel thickness - min.

- max.

8 mm (5/16")

40 mm (1 3/4")

Feed speed

11 m/min (36 FPM)

Feed motor

2.2 kw (3 HP)

Pressure section

First roller driven, two rollers idle

End trim unit - two motors

Cutting speed

Straight cut max.

.27 kw (1/3

HP ea)

12,000 RPM

5 x 45 mm (3/16" x 1 3/4")

Fine trimming unit

Tilting range

Cutter speed

.4 kw (1/2

HP ea)

0 - 15

°

12,000 RPM

Profile trimming unit - top and bottom

0.3 kw (1/2 HP ea - two motors)

Electronic frequency changer

Total power required

7 kw

Amperage @ 230

@ 460

40 amps

20 amps

Machine length

5240 mm (17' 2”)

Machine width

1730 mm (68")

Working height

900 mm (35.5")

Total height

1600 mm (63")

Machine net weight (with all stations full)

1950 kg (4290 lbs)

Electrical connection: 208/230 or440/480 volt, 3-phase, 60 Hz.

Dust extraction: 1 x 140mm ( 5 ½” ) 700 CFM, 1 x

100 mm (4"), 600 CFM.

Compressed air connection:

0.18 CFM per panel, 6 bar (85 PSI).

Automatic Height Adjustment with Top Pressure Beam forAll Top Work Stations

PC-16Program Control

Integratedelectronic line control system for increased reliability and diagnosticassistance

AutomaticMagazine for Strip and Coil Feeding

·

large coil table (800 mm diameter) with built-inrollers to allow for 3 mm PVC coils

·

edgestrip capacity from 0.4 mm to 8mm (0.016” –5/16”)

·

direction of glue roller reversible

·

glue roller section is also retractable fromfence line

·

one large driven pressure roller with pneumaticpressure control

·

two secondary rollers, all with controlled sidepressure

·

setting of pressure zone equipped with digitalcounter accurate to .1 mm (.004)

·

strengthened precutter for cutting thick PVCedges from the coil;

maximum 3 x 45mm;

precutting system equipped with airvolume reservoir for on-demand activation required for short workpieces

StandardGluing System

·

heat-up time is twelve minutes

·

quick-change glue tank for easy maintenance andglue color change, if necessary

·

glue temperature indication of both premelterand glue roller via LED thermostat display visible to operator

·

infrared radiant glue heat zone control foroptimum gluing strength

·

Automatic temperature reduction if not runwithin 15 minutes.

This feature lowersthe temperature automatically to 150 degrees C.

SoundCover

·

equipped with three independent openings

·

safety interlock system - when sound enclosuredoor is opened, corresponding work station shuts off

·

end trimming, fine trimming, and top/bottomcontour trimming motors are each equipped with electronic motor brakes to stopcutter rotation when hood is opened or when station is shut off at operatorcontrol panel

EndTrimming Station

·

straight/chamfer end trim unit equipped with two0.27 kw (1/3 HP) 12,000 RPM motors;

electronic motor brakes

·

end trim unit utilizes drawing cut system forreduced blade projection when working on thick panels

·

tooling also included

·

programcontrolled indexing from straight to bevel end trimming

FineTrimming Unit

·

equipped with two .4 kw (1/2 HP) 12,000 RPMtrimming motors

·

electronic motor brakes

·

horizontal and vertical tracing with laterallocation indexing via digital “Quickset” system calibrating to .1 mm (.004”)

·

tiltable from 0 - 15

°

·

each trimming motor is equipped with one dusthood and dust extraction hose

·

equipped with two combination straight/radiuscutterheads, including four knife carbide inserts set at shear angle foroptimum surface quality finish;

flushtrimming possible up to 8 mm edge thickness;

radius - 3 mm

·

programcontrolled pneumatic indexing

ContourTrimming Unit

·

for rounding front and trailing corners ofworkpieces with 3 mm PVC edgings

·

includes two trimming motors 0.3 kw (1/2 HP)12,000 RPM;

electronic motor brakes

·

equipped with 3 mm radius insert cutterheads -reversible

ScrapingUnit with Knives

BrandtUnit #5760

·

for scraping of roughly trimmed thick PVC edgesin order to remove the cutter marks

·

3 mm radius reversible profile knives standard

·

programcontrolled pneumatic indexing

Topand Bottom Buffing Unit

BrandtUnit

·

top and bottom buffing motors for finishing oflongitudinal edges

·

two 2800 RPM polishing motors

·

inclinable vertically and horizontally

·

two buffing wheels included